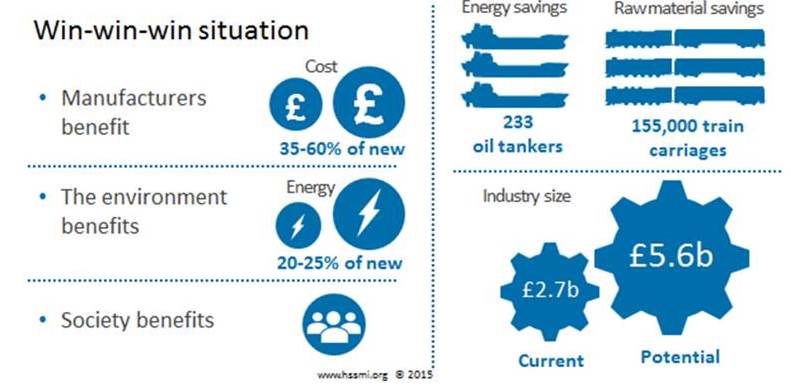

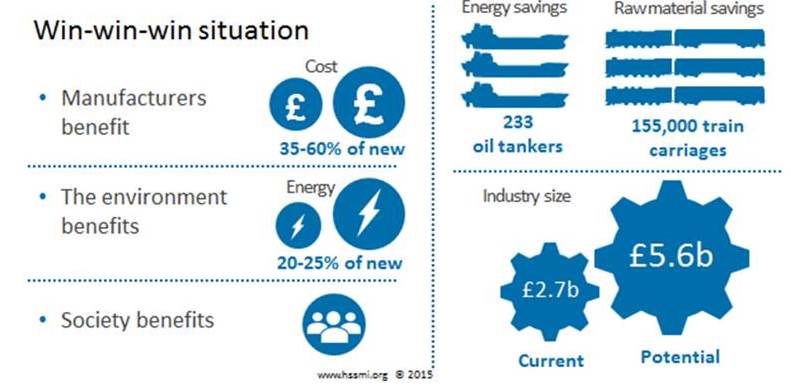

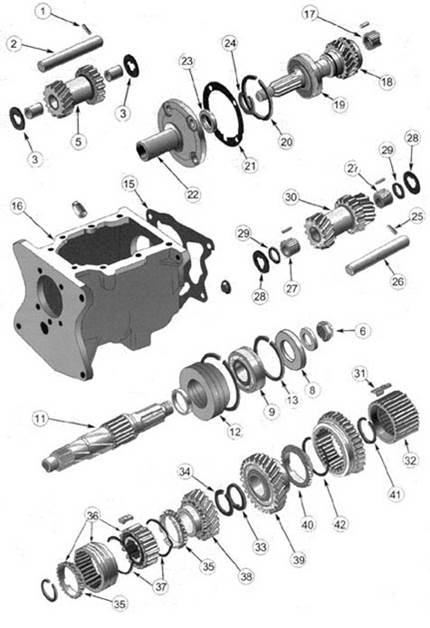

Remanufacturing is "the process of returning a used product to at least OEM original performance specification from the customers' perspective, and giving the resultant product warranty that is at least equal to that of a newly manufactured equivalent" (Ijomah 2002). Remanufacturing can be more sustainable than manufacturing de novo because it can be profitable and less harmful to the environment. Several industry sectors have reported substantial energy savings and CO2 emission reductions.

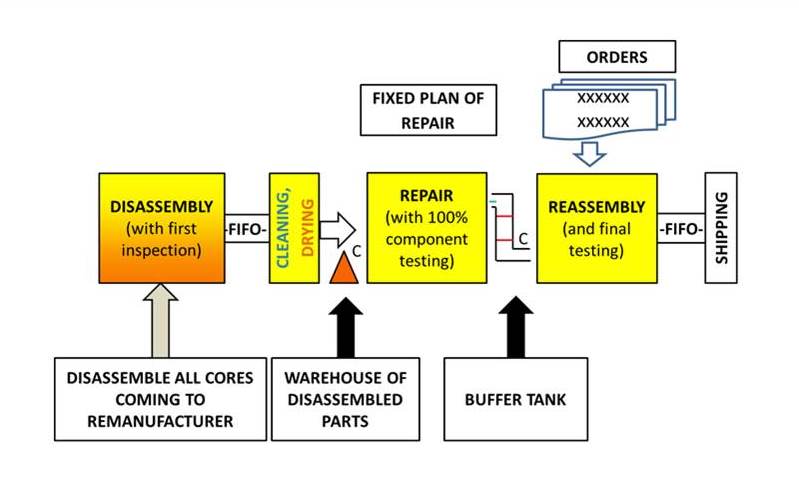

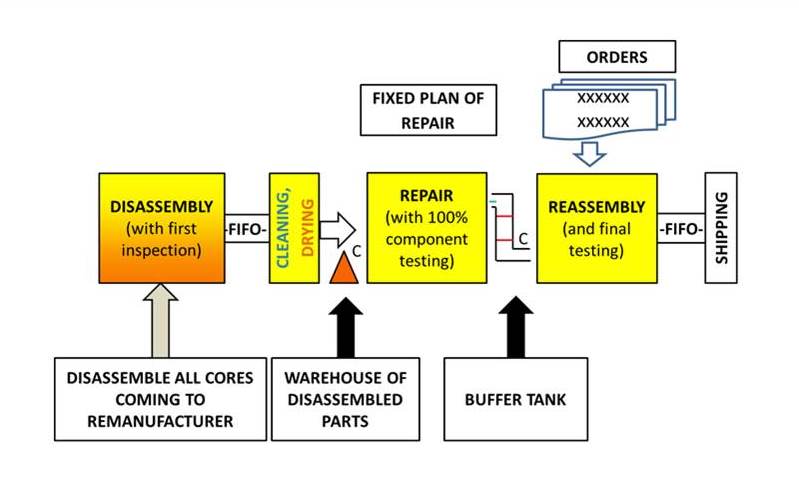

A key step in remanufacturing is the disassembly of the "core", or the returned product to be remanufactured. In many ways, disassembly is more challenging than assembly to automate due to variability in the condition of the core. As it is complex, disassembly tends to be manually executed and is labour intensive.

AUTOREMAN is a five-year EPSRC-sponsored multi-disciplinary project focussing on remanufacturing as a means to sustainable manufacturing.

AUTOREMAN will develop robotic technology enabling disassembly to be carried out with minimal human intervention or in a collaborative fashion by man and machine. In many situations, robots will function autonomously, alongside people who will perform tasks that are too difficult or too costly to robotise. In other situations, robots will assist human operatives, as equal co-workers or as subordinates to humans.

AUTOREMAN will start with a detailed investigation of disassembly processes in order to derive the necessary fundamental understanding. The acquired basic process knowledge will be used methodically to create plans, models, algorithms and tools to enable robotic systems to carry out disassembly autonomously or in cooperation with humans.

AUTOREMAN is structured along four successive research objectives: